Pul Pehlad Pur, delhi

- GST NO. : 07ABICS9491D1ZX

| Business Type | Manufacturer, Exporter, Supplier |

| Download | |

| Country of Origin | India |

| Type | Effluent Treatment Plant |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

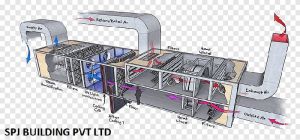

Zero liquid discharge system – ZLD- ETP ZLD -ETP

Zero Liquid Discharge (ZLD) is a water treatment process with a goal of recirculation of all of the possible water back to the process with zero liquid waste. The ultimate treatment process has zero or nearly zero adverse impact on the environment.Pre-treatment - reducing TSS, COD, Turbidity to filter out particle impurities or precipitation of sparingly soluble compounds to allow additional treatment.

Concentration of dissolved solids - by membrane technologies, either by a combination of reverse osmosis (RO) with electrodialysis (EDR). The way of concentrating RO brine by EDR. Or single step electrodialysis. Using these technologies to concentrate the stream we can achieve more than 98 % of recovery.

Thermal treatment - the last step is usually consisting of Evaporator/Crystallizer to generate solids. Final evaporation of remaining water for re-use together with precipitation of solid waste for disposal in a controlled landfill or to be sold as a valuable product (pure NaCl Na2SO4 etc.)

ADVANTAGE OF ZLD

Zero liquid discharge plant technology is growing globally as an important wastewater management strategy to reduce water pollution and extend water supply.

The main benefits of ZLD are :

- Minimizes Wastewater Discharge, Maximizes Water Recovery.

- Create A Valuable Product For Sale, Removing Environmental Issues.

- Reduction Of Dependence On Local Water Sources And Local Legislation.

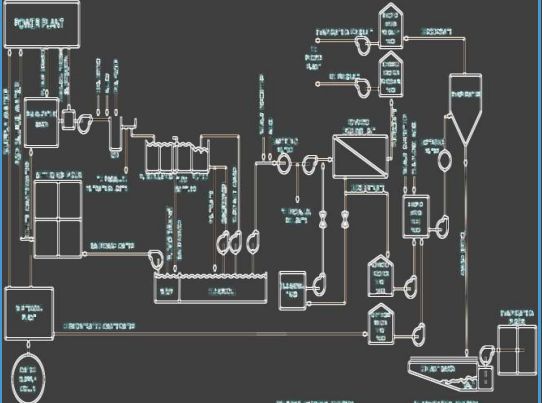

What’s included in a basic ZLD treatment system?

- The exact components of a ZLD treatment system will largely depend on the volume of

- dissolved material present in the waste, the system’s required flow rate what specific

- contaminants are present. But in general, a basic ZLD treatment system typically

- includes some type of :

- Clarifier And/or Reactor To Precipitate Out Metals, Hardness, And Silica

- Chemical Feed To Help Facilitate The Precipitation, Flocculation, Or Coagulation Of Any Metals And Suspended Solids

- Filter Press To Concentrate Secondary Solid Waste After Pre-Treatment Or Alongside An Evaporator

- Ultrafiltration (UF) To Remove All The Leftover Trace Amounts Of Suspended Solids And Prevent Fouling, Scaling, And /Or Corrosion Down The Line Of Treatment

- Reverse Osmosis (RO) To Remove The Bulk Of Dissolved Solids From The Water Stream In The Primary Phases Of Concentration

- Brine Concentrators To Further Concentrate The Reject RO Stream Or Reject From Electrodialysis To Further Reduce Waste Volume

- Evaporator For Vaporizing Access Water In The Final Phases Of Waste Concentration Before Crystallizer.

- Crystallizer To Boil Off Any Remaining Liquid, Leaving You With A Dry, Solid Cake For Disposal.

Graph Image

Looking for "Effluent Treatment Plant" ?

Explore More Products